PET Metalized Thermal Lamination Film

- hubei

- 30 days after deposit

- 10 tons/day

1.thickness:12-75 micron

2.width:240-1650mm

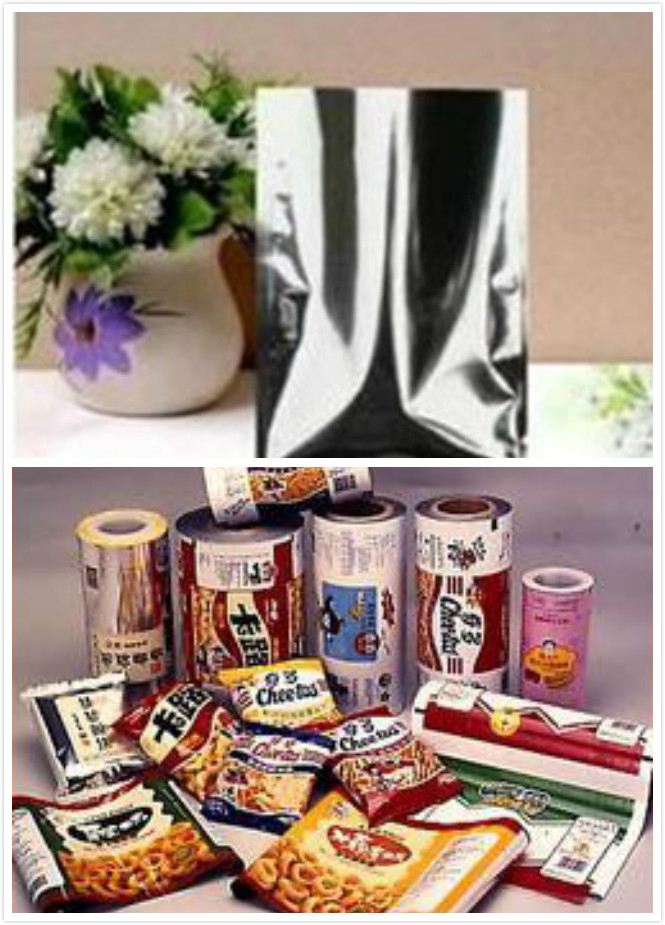

3.PET metalized thermal lamination film is popular used for food and gift packing,or laminating and others.

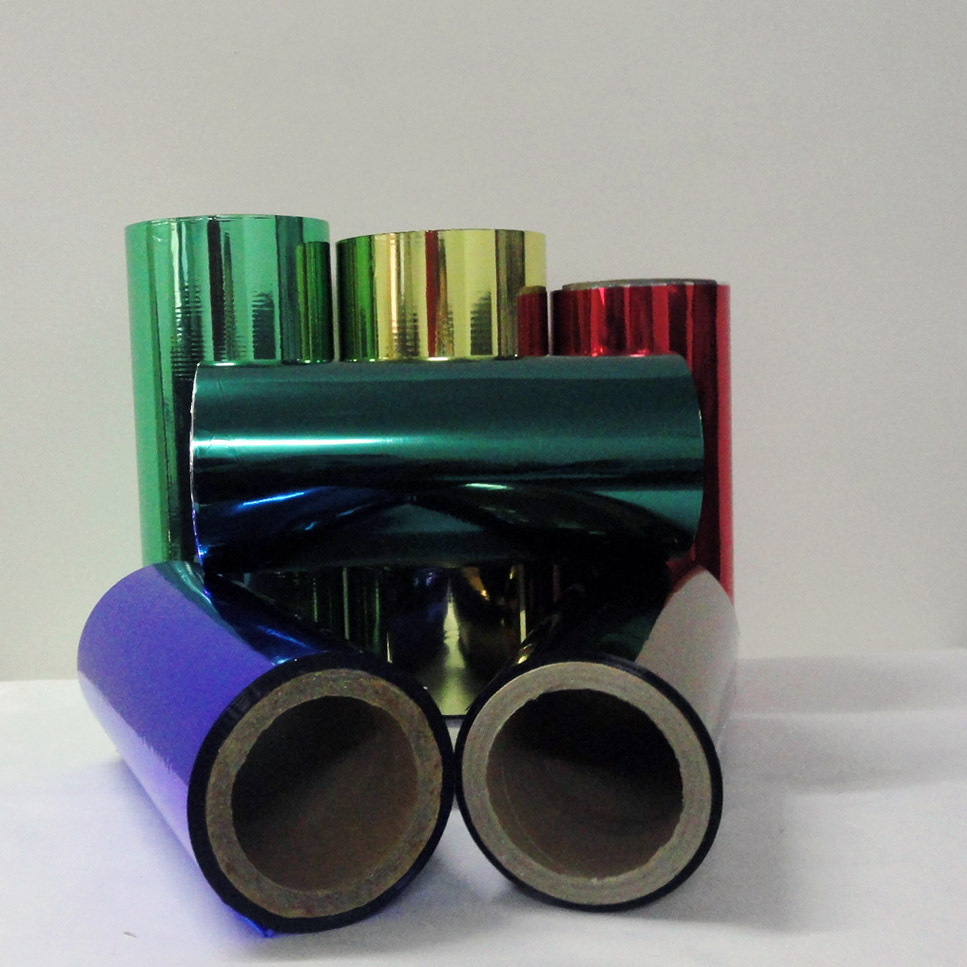

4.you can cut this color vmpet film into specified sizes as your request

5.the usage of PET metalized thermal lamination film:1).Be used as soft-package for food,medicines and cosmetic etc

2).Be used as a ornament film,such as string of flower crafts,christmas flowers,etc

3).Be used for compound printing or cardborad composite

Feature of PET metalized thermal lamination film

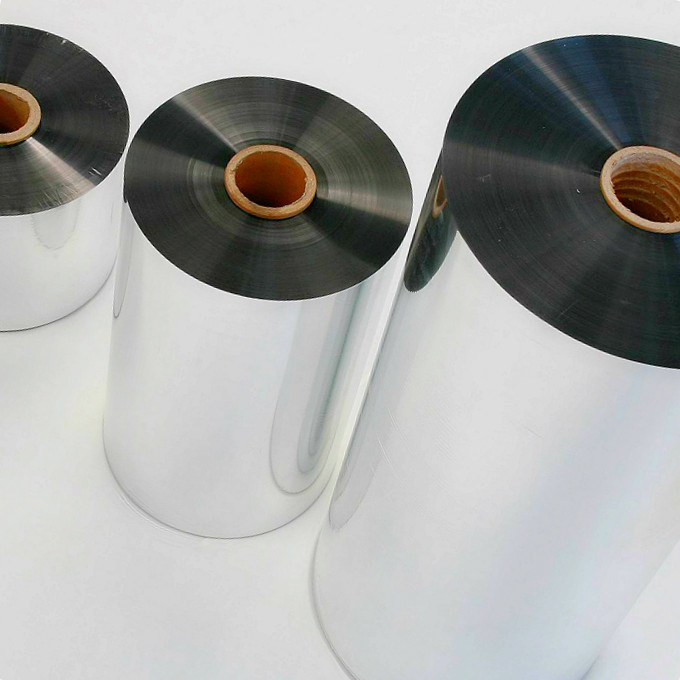

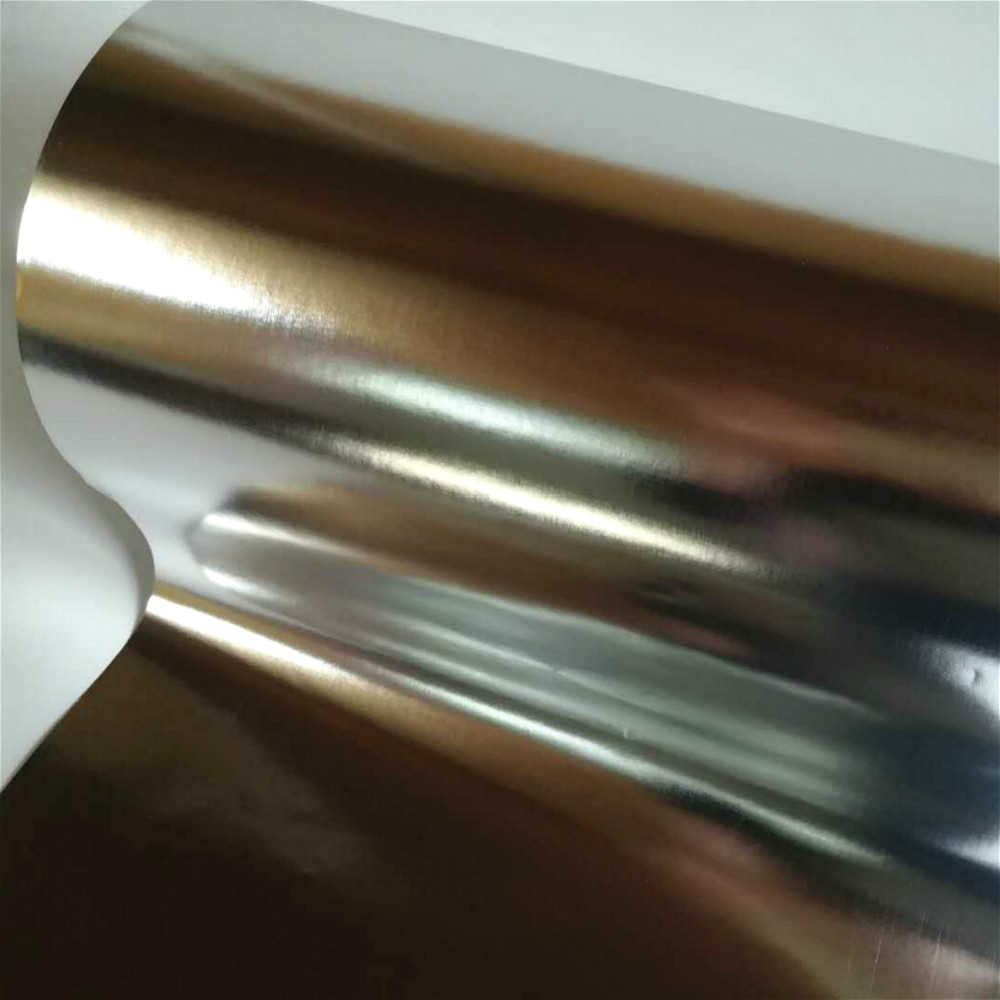

1) High gloss and high smoothness of surface,

2) Strong metallic look and excellent aluminum adhesion.

3) Good printing quality and fireproof properties

4) Heat resistant, water proof, stable at high temperature or in boiled water

5) Environmentally friendly, no smell and non-toxic

Our Services

1. Custom-made and OEM service are available.

2. Strong package for long way shipment.

3. Trial sample are acceptable based on customers requirement.

4. Best quality and stable supply.

5. Fast goods delivery.

6. Bottom price are always offered.

7. Flexible payment terms.

8. Near convenient loading port at Shanghai or Wuhan.

9. Quickly response of customers' questions

Data sheet for PET metalized thermal lamination film

| Test Item | Unit | Standard | Test Method | |

| Thickness | mic | 12 | ASTM D-374 | |

| Tolerance | % | ±3 | ||

| Tensile strength | MD | Kg/mm2 | ≥18 | ASTM D-882 |

| TD | ≥18 | |||

| Elongation at break | MD | % | ≥100 | ASTM D-882 |

| TD | ≥100 | |||

| Heat shrinkage (150℃,30min) | MD | % | ≤3.0 | ASTM D-1204 |

| TD | ≤3.0 | |||

| Surface Tension | dyn | ≥50 | ASTM D-2578 | |

| Friction Coefficient | —— | ≤0.80 | ASTM D-1894 | |

| ≤0.80 | ||||

| Base Film Haze | % | ≤3.0 | ASTM D-1003 | |

| Thickness of Aluminum Layer | Å | 380 | Square resistance meter | |

| Ω/□ | 1.5 | GB/T 15717 | ||

| O.D | 1.8 | X-rite 361 | ||

| Uniformity of Aluminum Layer | % | ±10 | GB/T 15717 | |

| Firm of Aluminum Layer | % | 100 | 3MTape | |

Factory overviews