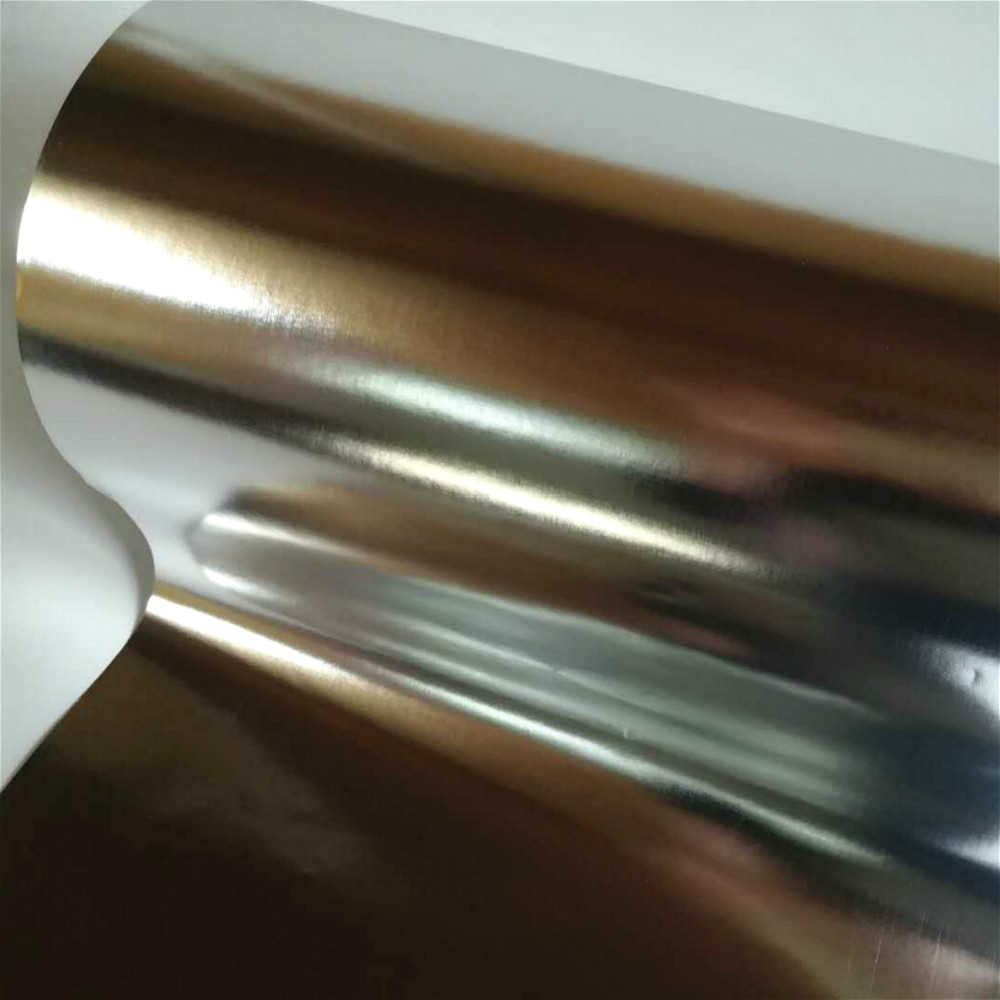

Silver Metallic Printing Paper

- hubei

- 30 days after deposit

- 10 tons/day

1.we have two types of silver metallic printing paper,one is standard and the other is ink-retention.

2.the surface for wet strength label paper are plain and lots kinds of embossed style.

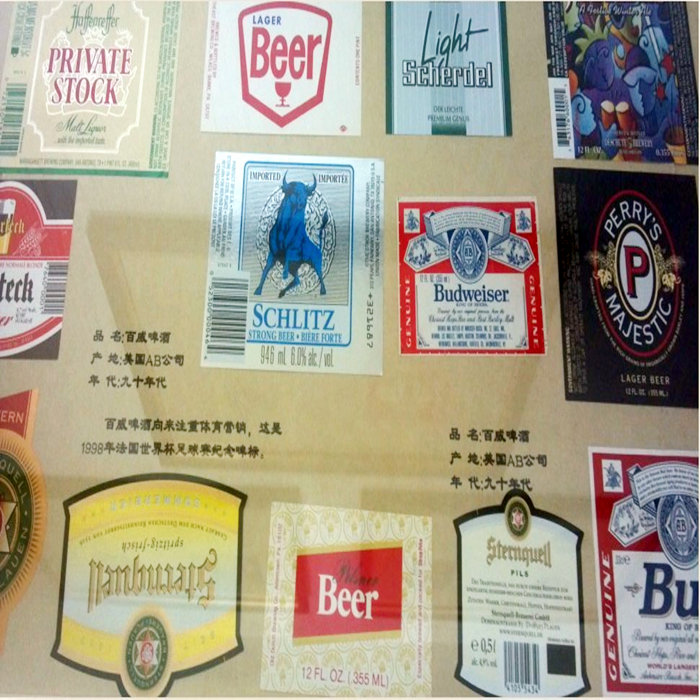

3.We produce silver color metallized paper for beer label printing.

4.the grammage of the paper we produce is from 68 to 86gsm.

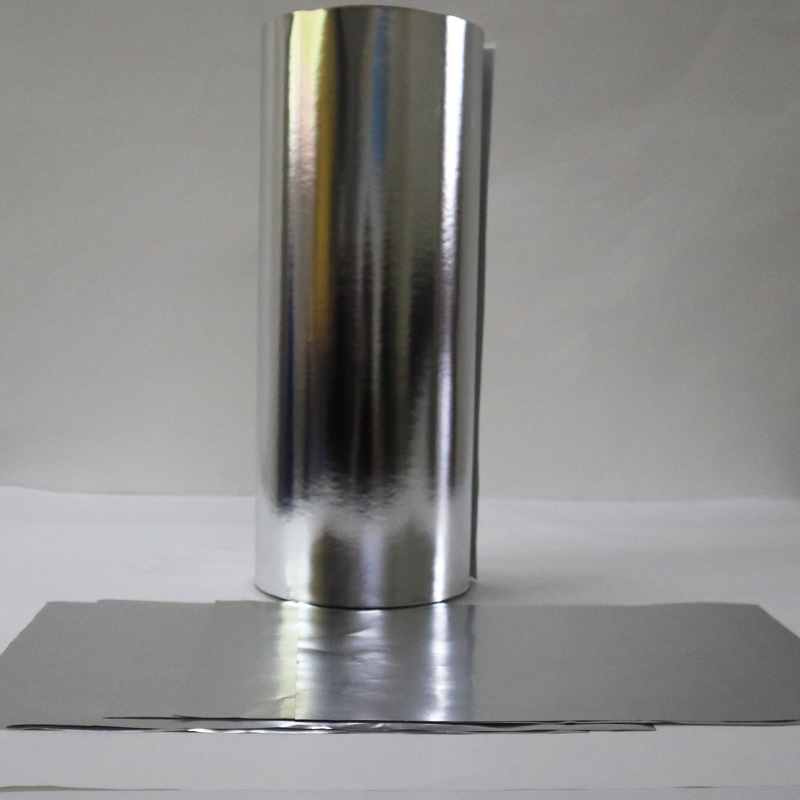

5.Shade:in roll and in sheets.

Silver metallic paper characteristic:

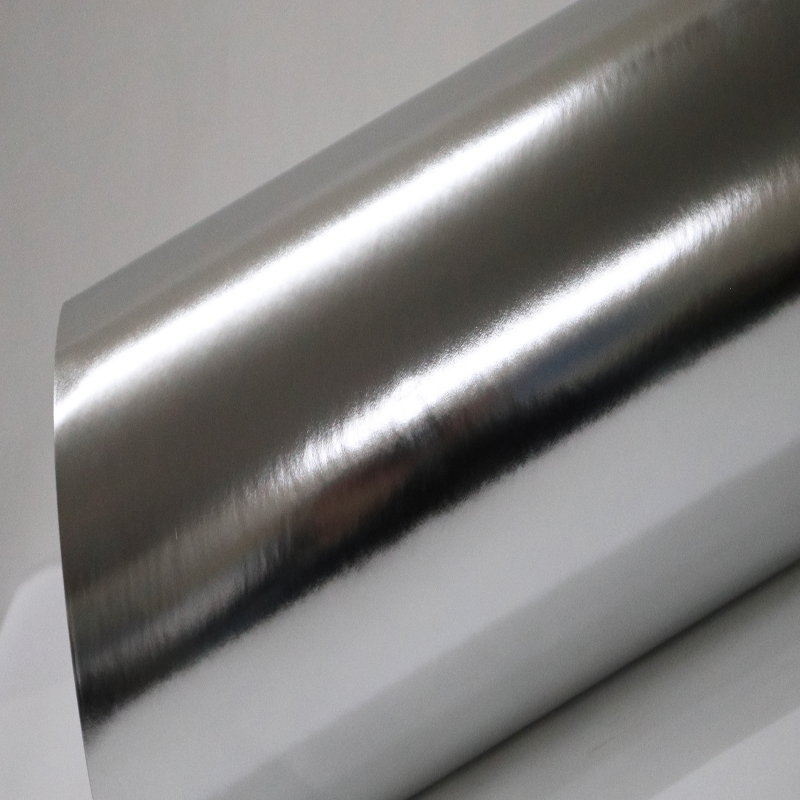

1 High gloss strong metallic look, not be oxidized& blackiness.

2 Surface is free from unmetallized spote,scratches,dents,pinholes,bubbles.

Silver metallic printing paper

General Introduction :

Vacuum metallized paper as a kind of vacuum aluminum packaging material is a new type of environmentally friendly composite packaging material. It gradually replaced the aluminum foil laminated paper as the paper substrate. It is recyclable and is a kind of environmentally green packaging material. Most European countries use it on the gifts, toys, food, alcohol and tobacco, cosmetic products’ packing and printing .

Product show and features :

1 High brightness and great adhesive force for printing ink

2 Used in beer/liquor/spirits label paper and can pack label paper;

3 Suitable for offset and gravure printing;

4 Great for high speed machine to attach label automatically;

5 Easy to wash away from bottles;

6 Belong to environmentally-sound products.

7 Their coatings are odorless, nontoxic, and easy to recycle, and have good degradation and water solubility.

Data sheet for silver metallic printing paper

| Test Item | Unit | Test Method | Value | |

| grammage | g/m2 | GB/T450 | ±3 | |

| Moisture | % | GB/T462 | 5.5±1 | |

| Wet strength | MD | KN/m | GB/T465.2 | ≥1.0 |

| TD | KN/m | GB/T465.2 | ≥0.7 | |

| Tensile Strength | MD | KN/m | GB/T453 | ≥3.5 |

| TD | KN/m | GB/T453 | ≥1.8 | |

| Break Load | MD | mN | GB/T455.1 | ≥350 |

| TD | mN | GB/T455.1 | ≥350 | |

| Reverse Side COBB (60s) | g/m2 | GB/T1540 | 15±5 | |

| Wet Tensile Strength | mN/m | GB/T14216 | ≥36 | |

| Aluminum Firmness | % | _________ | ≥95 | |

| Alkali Resistance | S | _________ | ≤90 | |

| Gloss(45°) | % | GB/T8941.2 | EMBOSSED≥200 | |

| ____ | _________ | PLAIN≥300 | ||

| Smoothness | S | GB/T456 | EMBOSSED≥600 | |

| _________ | _________ | PLAIN≥1000 | ||

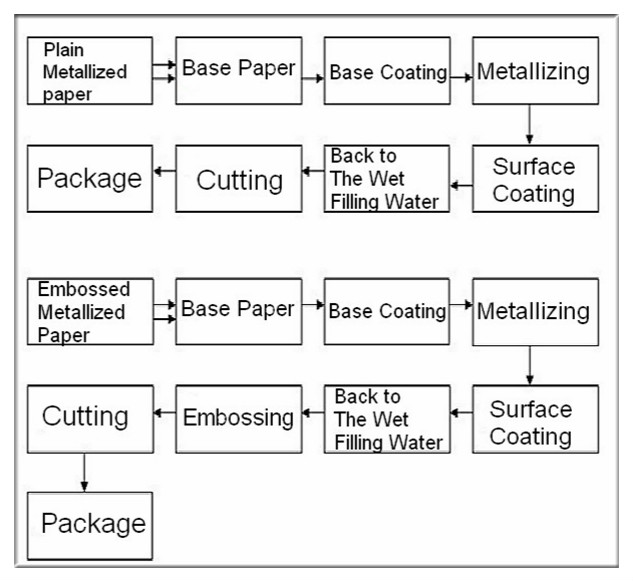

Production process flow chart