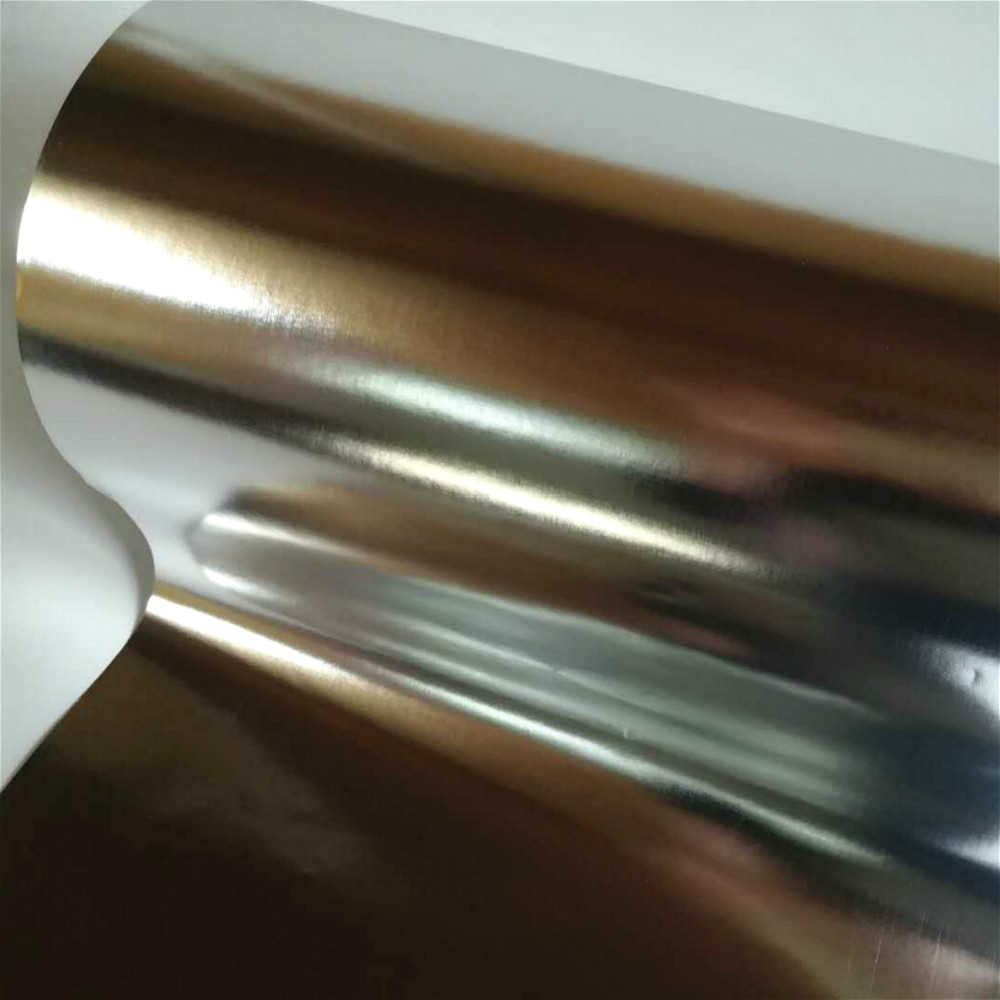

Silver Pet Film

- hubei

- 30 days after the deposit

- 10 tons/day

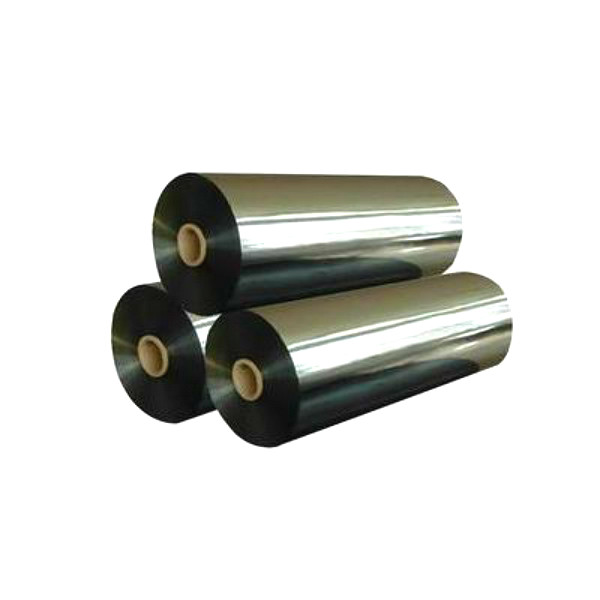

1.thickness:12-75 micron

2.width:240-1650mm

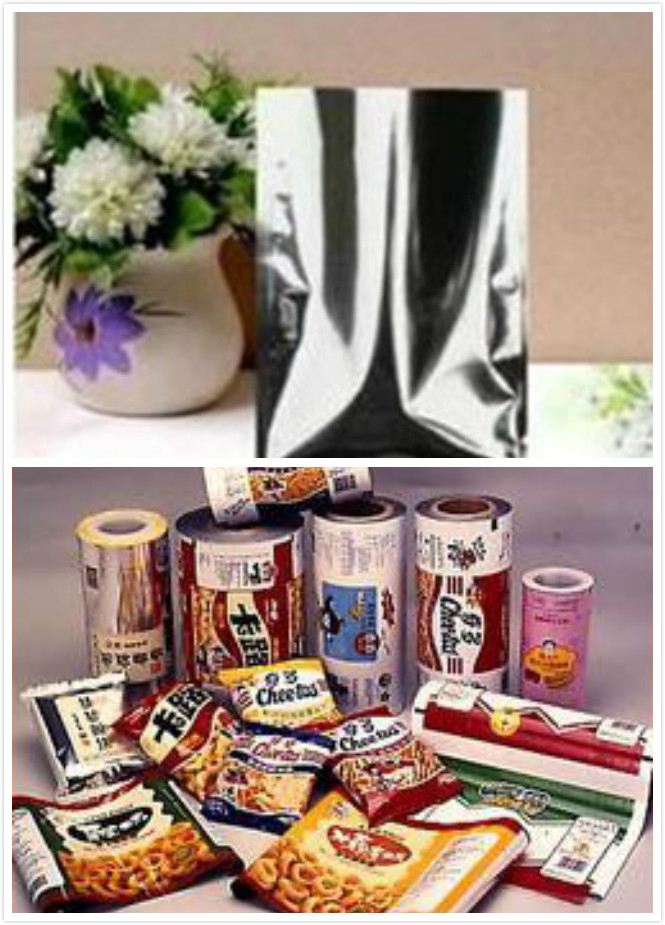

3.vmpet film is popular used for packing biscuit, candy, tea, coffee, chocolate, dried food, flavorit. It is also widely used as the lining of the compound food package, such as popcorn, instant noodles, puffing food,etc.

4.you can cut this silver pet film into specified sizes as your request

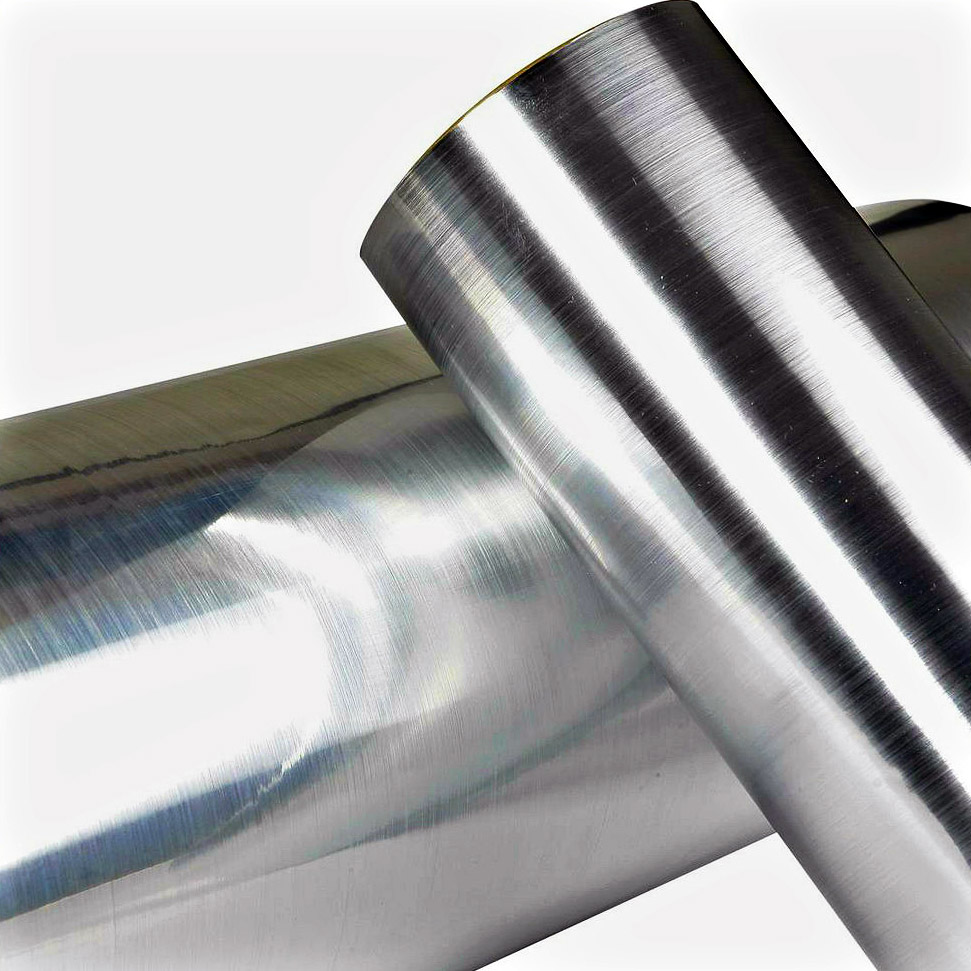

5.the advantage of high glossy vmpet film:high glossy,strong metallic looking,smooth surface

1.Feature of silver pet film

● This Emergency Blanket provides personal protection from rain, wind, heat, and cold.

● It's made from PET, extremely lightweight, flexible, space-age material. It can retain up to 90% body heat in cold weather.

● It even deflects heat in hot climates and can be used to offset hypothermic reactions.

● The Emergency Blanket is waterproof, reusable, and portable. It's perfect for camping trips and sporting events in addition to emergencies.

2.Our Services

After Sales: |

1. We are very glad that customer give us some suggestion for price and products. |

2. If any question, please let us know it in the first by E-mail or Telephone. We can deal with them for you in time. |

Factory Visit: |

1. Welcome any customer to visit our factory directly. |

2. If customer have any scheduling in China, please let us know. We would llike to help you book the hotel and pick up you from air port, or railway station. |

3. Any more problems, please feel free to ask, and we will try our best to supply you! |

Additional: |

Looking forward to your kindly inquiry |

3.Data sheet for silver pet film

| Test Item | Unit | Standard | Test Method | |

| Thickness | mic | 12 | ASTM D-374 | |

| Tolerance | % | ±3 | ||

| Tensile strength | MD | Kg/mm2 | ≥18 | ASTM D-882 |

| TD | ≥18 | |||

| Elongation at break | MD | % | ≥100 | ASTM D-882 |

| TD | ≥100 | |||

| Heat shrinkage (150℃,30min) | MD | % | ≤3.0 | ASTM D-1204 |

| TD | ≤3.0 | |||

| Surface Tension | dyn | ≥50 | ASTM D-2578 | |

| Friction Coefficient | —— | ≤0.80 | ASTM D-1894 | |

| ≤0.80 | ||||

| Base Film Haze | % | ≤3.0 | ASTM D-1003 | |

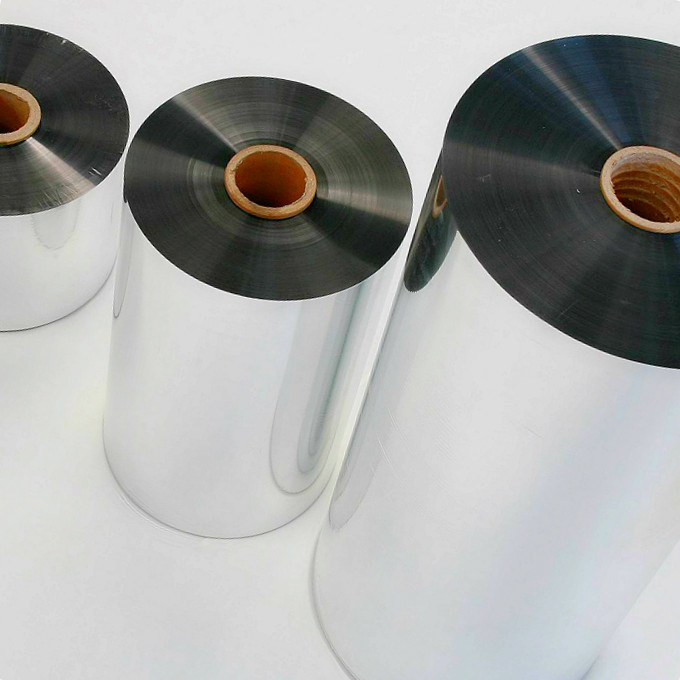

| Thickness of Aluminum Layer | Å | 380 | Square resistance meter | |

| Ω/□ | 1.5 | GB/T 15717 | ||

| O.D | 1.8 | X-rite 361 | ||

| Uniformity of Aluminum Layer | % | ±10 | GB/T 15717 | |

| Firm of Aluminum Layer | % | 100 | 3MTape | |

4.Production Process:

1. transparent film

2. metalized film

3. metalized film with color coating.

4. rewinding and slitting

5. packing

5. Product and factory show